Similar content being viewed by others

Model-based modular hydrogel design

Article 26 March 2024

Ultrastiff metamaterials generated through a multilayer strategy and topology optimization

Article Open access06 April 2024

Near-room-temperature water-mediated densification of bulk van der Waals materials from their nanosheets

Article 15 March 2024

Introduction

Fiber-reinforced polymer (FRP) composites have been widely used in aviation/aerospace structures1, shipbuilding, and other industrial fields due to their good corrosion resistance, high strength-to-weight ratio, and strong designability. These inherent advantages have propelled FRP composites towards becoming a pivotal reinforcement material in civil engineering2,3 and have been increasingly used in new construction4,5,6 over the past two decades. However, the ability of FRP composites to resist damage during long-term service, i.e., durability, in the face of complex service environments has become one of the most important scientific issues in the field of engineering.

The study of material damage is closely related to surface/interface issues, particularly for FRP composites, which are characterized by the interfaces between fibers and the polymer matrix. Therefore, an appropriate interface model that transfers the results obtained from atomic/molecular simulations to continuous medium simulation is essential for achieving cross-scale modeling. Additionally, microscopic defects such as bubbles and voids are inevitably introduced during the production process of FRP composites7. Even pure epoxies (e.g., amine-cured epoxies) contain nanopores that enable the transport and storage of moisture8. Given the various service conditions, FRP composites may be subjected to a combination of different environmental loads (e.g., ultraviolet radiation from sunlight; freeze-thaw cycles; diurnal/seasonal temperature changes; moisture from humidity, rainfall, immersion, or seawater; and alkaline solutions from concrete pore water)9. These external environments, particularly when combined with the aforementioned microstructures, may lead to the deterioration of FRP composites, ultimately impacting their durability. Hence, there is an urgent need to investigate the microscopic mechanism, identify a suitable coupling method, and integrate cross-scale simulations to achieve a quantitative explanation of the macroscopic phenomenon of deterioration.

With the advancement of experimental technology and simulation methods below the microscale10, an increasing number of researchers are attempting to explain the corresponding macroscopic phenomena from a microscopic perspective. In experiments, scanning electron microscopy (SEM) and transmission electron microscopy (TEM)/high-resolution TEM have been used to observe the microstructure of FRP composites11,12,13,14, such as fiber-matrix interfaces, microcracks, voids in a matrix, etc. The fine details of microstructure provide an intuitive reference for computational modeling and understanding of the deterioration mechanism of materials. Atomic force microscopy (AFM) has been used to investigate the microstructure and mechanical properties of FRP composites15,16, such as the local modulus of the sample. X-ray computed tomography (CT) can non-invasive capture the three-dimensional structure of the material17,18 and provide the internal pore distribution and porosity, as well as generate a three-dimensional model for simulation or mechanical performance analysis. The glass transition temperature (Tg) and thermodynamic properties of epoxy can be determined by differential scanning calorimetry (DSC)12,14. X-ray photoelectron spectroscopy (XPS), Fourier transform infrared spectroscopy (FTIR), and Raman spectroscopy are available to characterize and analyze the changes in the chemical components and molecular structure of FRP composites under different environmental conditions11,12,14,19, such as functional group and hydrogen bond. These experimental methods not only offer direct evidence for understanding the microscopic mechanisms but also provide reference and comparison for modeling and analysis of simulations, thus enabling the understanding of microscopic mechanisms from the atomic scale to the macroscale.

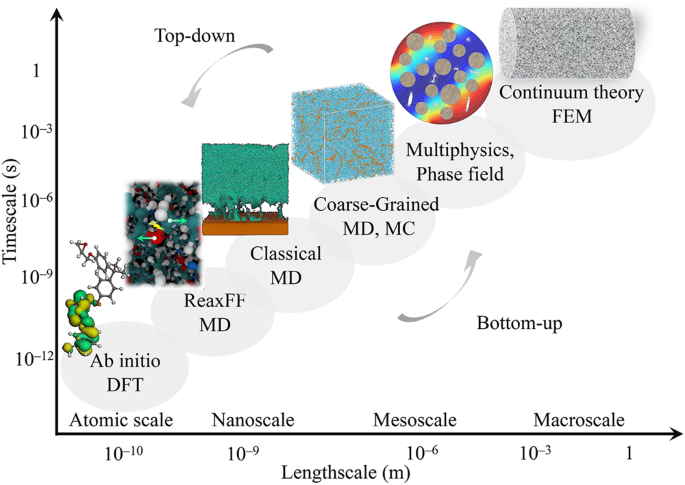

Multiscale simulation methods have been developed gradually, such as density functional theory (DFT), ab initio molecular dynamics (AIMD), reactive force field (e.g., ReaxFF) MD, classical MD, coarse-grained (CG) MD, Monte Carlo (MC) method, phase field method, finite element method (FEM), etc. The multiscale covers the atomic scale, nanoscale, mesoscale (or microscale), and macroscale (> 10‒3 m) as shown in Fig. 1, with this paper focusing on the scale that ranges from the atomic scale to the mesoscale. It should be noted that there is currently no uniform division of different scales and no absolute boundary between adjacent scales but a transitional area20, and this paper only divides the scale characteristics of FRP composites. Different theories and methods are required to deal with issues at different scales. At the atomic scale, quantum effects and charge transfer need to be considered, such as in the cross-linking reaction of polymer curing, material corrosion, and other chemical reactions. At the nanoscale, issues related to nano mechanics are considered, including nonbonding interactions (i.e., van der Waals interaction and hydrogen bond). For example, the adhesion between polymeric matrix and fibers mainly involves nonbonding interactions, and only a few specially treated fibers are additionally bonded by chemical bonds21,22. The mesoscale is where continuum mechanics and nano mechanics converge20. At the mesoscale, defects, interfaces, and nonequilibrium characteristics are common. The formation of microcracks and voids all involve interface problems, and the problems of voids in FRP composites are particularly important at the mesoscale. At this scale, more attention is paid to the problem of multifield couplings, such as the changes in the internal structure and mechanical properties of FRP composites under coupling effects of moisture, seawater, temperature, and voids. For instance, in a humid environment, water enters the interior of the FRP composite due to capillary action and diffusion, which affects the properties of the matrix and interface23. The most common macroscale methods are FEM simulations and experiments, which are widely used in the study of mechanical properties, and many models have been established in the study of FRP composites. In cross-scale modeling, the transfer of physical quantities in the transition area is a critical issue.

Fig. 1: Multiscale simulation framework of FRP composites.

It describes a bottom-up approach that comprises Ab initio, DFT, ReaxFF MD, Classical MD, CGMD, MC, Phase field, and FEM simulation methods and displays the time and length scales corresponding to each simulation method along with the corresponding schematic models.

Full size image

MD simulation has played a crucial role in bridging the gap between quantum chemistry and continuum mechanics, as shown in Fig. 1. It is a fundamental and versatile tool that can simulate the molecular structure and investigate the mechanical, chemical, and thermodynamic properties of materials from the atomic/molecular level. However, as MD simulations use a single atom or molecule as the simulation unit, the trajectory of all particles in phase space must be obtained by solving the Hamiltonian equation of the entire system, leading to extensive calculations and limiting the size of the simulation system. Macroscale failure or debonding of the structure is a large-scale disaster that involves a large time and spatial scale. As a result, establishing a direct relationship between nano/microscopic results and macroscopic phenomena is a challenge for MD simulation. Bridging the nano/microscale and the macroscale is both a challenge and an opportunity for interdisciplinary research. To this end, many research teams have proposed multiscale research methods to overcome the limitations of MD simulation24,25,26.

This review first provides a brief overview of the interdisciplinary and multiscale problems encountered in the study of the durability of FRP composites. It discusses the various factors, such as temperature, ultraviolet radiation, humidity, seawater, and corrosive action, that influence the properties of FRP composites, leading to thermodynamic, mechanical, chemical, and multifield coupling problems. It also introduces the accelerated method for durability testing and its applicable conditions. Since the deterioration of FRP composites during service involves interface problems, such as debonding, fracture, and delamination, two typical interface models are introduced. To understand the durability and deterioration mechanism of FRP composites from the nano/microscale perspective, the review introduces related physical and mechanical issues, such as van der Waals interaction, hydrogen bond interaction, disjoining pressure, and capillary action. After introducing these interdisciplinary backgrounds and foundations, the methods of bridging length and time scales in the durability studies of FRP composites are reviewed. It mainly introduces related multiscale simulation methods and their corresponding theories, as well as the physical parameters available at each length scale. MD simulations have played a bridge role between quantum chemistry and continuum mechanics in multiscale modeling. Therefore, the review provides a detailed overview of atomic- and molecular-scale simulations of FRP composites, including ReaxFF MD, classical MD, and CG MD, in the study of their mechanical properties and durability. Moreover, the review briefly introduces the problem of multiscale voids in FRP materials. While it is impossible to cover all advances in the field of micro- and nano-research of FRP composites in a single paper, this review focuses on a few typical topics of the vast subject. Due to the complexity of the subject and the limited knowledge of the authors, there may be inevitably neglected topics and deficiencies. Nonetheless, the main purpose of this review is to clarify the role of multiscale simulation methods, especially MD simulations, in FRP composite research and outline its prospects, hoping to illustrate how micro- and nano-mechanics contribute to FRP durability research.

#fiberreinforcedcomposite#polymer#fiberreinforcedconcrete#fiberreinforcedpolymer#sciencefather#sciencefiction#scientists#frpinnovation#fiberawards#sciencefather#FRP#CompositeMaterials#PolymerMatrix#HighStrengthFibers#Lightweight#StrengthAndDurability#StructuralApplications#EngineeringInnovation#MaterialsScience#CivilInfrastructure#AerospaceTechnology#AutomotiveIndustry#ManufacturingTechniques#FiberArchitecture#FunctionalComposites#SmartMaterials#SustainabilityMatters#environmentalimpact

No comments:

Post a Comment